At our core, we are committed to sustainability. Our Recycled rubber compound is one of transformation and a commitment to reducing waste and environmental impact, whilst contributing to a circular economy or as a lifecycle extension, allowing for pavements to be used again if that practice is employed within the industry.

REVPOL

As demand for tyres continue to grow, innovative recycling methods and sustainable practices are essential for a greener and more sustainable future. These innovative compounds are derived from end of life tyres, a resource that typically ends up as waste.

Through proprietary technology, we take processed tyre crumb rubber from discarded tyres and transform it into a high value recycled rubber compound, ensuring that no resource goes to waste.

Formulating REVPOL

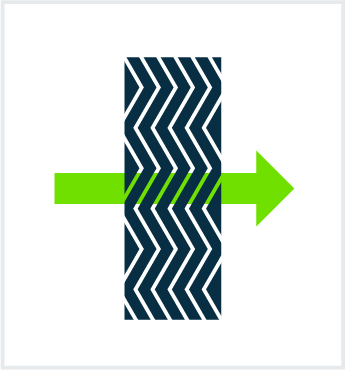

The process is quite remarkable. We start with processed tyre crumb rubber, the main product of current tyre recycling practices. This tyre crumb, would otherwise contribute to waste and environmental concerns, is revitalised through proprietary technology and re-processes it, returning it much of the way to its virgin state.

The rejuvenation of virgin properties through the reclaiming process allows us to create a rubber compound that is more functional and widely applicable to rubber manufacturing and road building processes but also contributes to a sustainable and eco-friendly approach to resources.

REVPOL PROCESS

Reducing the Need for Natural Resources

One of the key advantages of our Recycled Rubber Compound is its ability to substitute natural resources like natural rubber. By utilising end-of-life tyres, we reduce the demand for new natural rubber production, which can have a significant environmental impact. This sustainable approach not only conserves resources but helps reduce the environmental footprint of various industries.

Versatile Applications

Our Recycled Rubber Compound possesses both natural and synthetic rubber fractions, making it versatile and adaptable to a wide range of applications. Whether it's as a percentage masterbatch or a blend, these compounds can find their place in numerous industries, helping you meet your performance and sustainability goals.

Join us in making a positive impact on the environment while benefiting from the versatility and eco-friendly properties of our Recycled Rubber Compound. It's a win-win for your business and our planet.

RECYCLED RUBBER COMPOUNDS

Pavements

The future of pavements is a harmonious combination of sustainability and performance. Faced with a global challenge of waste tyres, REVYRE introduces REVPOL, our innovative Recycled Rubber Polymer Compound, to transform and enhance your pavements responsibly.

Benefits of REVPOL

-

Economical

More attractive than using virgin NR and SBR/S, making it a better option for businesses looking to reduce their costs.

-

Sustainable

REVPOL reduces the amount of waste generated by end-of-life tyres, which creates a significant environmental impact, if not properly disposed of. REVPOL helps to preserve natural resources.

-

Durable

REVPOL has similar or even better physical properties than virgin NR and SBR/S, including tensile strength, elongation and tear resistance, making it a durable and reliable material.

-

Improved Performance

Adding REVPOL to other materials, such as asphalt, realises improved performance characteristics, such as increased elasticity and improved resistance to cracking.

Want more information?

Download the REVPOL Product Sheet

Get in touch.

Contact us now to learn more about our repurposing process and start your sustainability journey today. Fill out our contact form and one of our experts will get back to you as soon as possible.